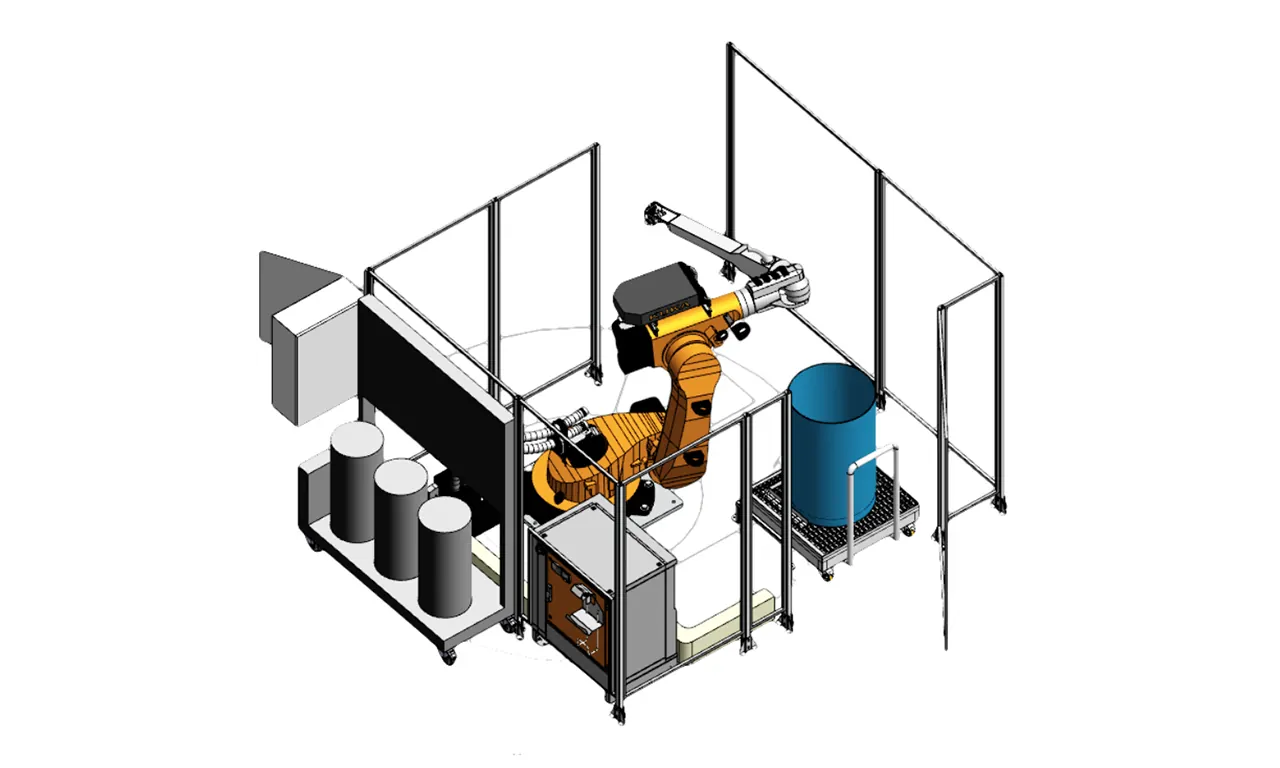

Robotized moulds lubrication

Mould lubrication is a simple activity that requires good planning. It starts by studying a solution that considers the accesses to the mould and the type of lubrication to be obtained, to develop a reliable and economical solution. The application that we propose as an example is hot forging on a press. Three different types of graphite and/or boron solutions can be used. The system is able to automatically wash the pipes up to the nozzles before product changes. There are alarms for clogging of the guns, end of product, lack of air/water, safety devices and scheduled maintenance deadlines. In addition to the guns, blowing nozzles are also installed for cleaning the mould. The system is remotely controllable and provides different recipes and robot paths depending on the mold and product. The attached video details the movements of one of the test paths during the assembly and calibration of the machine at the customer.